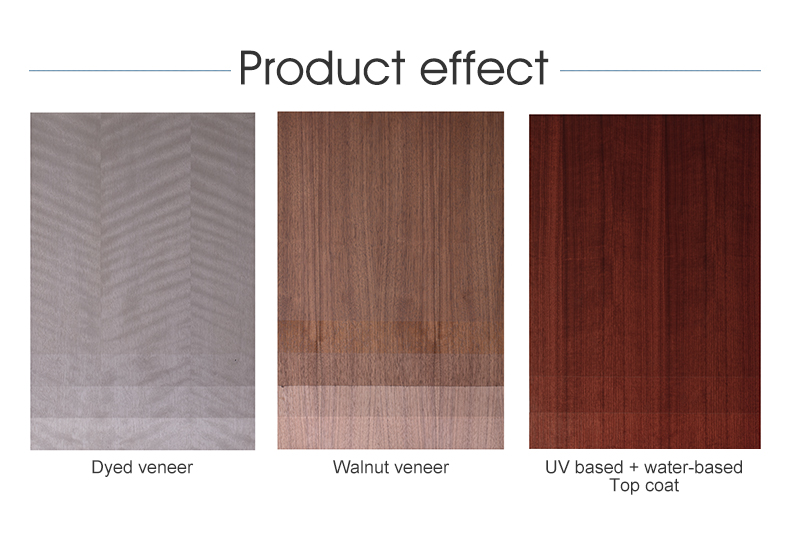

GTX-E13 is made of high-performance polyurethane dispersion coating with special synthetic process. It is suitable for sealing the bottom layer of high-grade dyed veneers and can effectively prevent dyed veneers from yellowing,also can be used as primer and provide excellent sealing and filling effect.

[Product Overview]

GTX-E13 is made of high-performance polyurethane dispersion coating with special synthetic process. It is suitable for sealing the bottom layer of high-grade dyed veneers and can effectively prevent dyed veneers from yellowing,also can be used as primer and provide excellent sealing and filling effect.

[Scope of application]

Sealing coating for high-grade customized furniture.

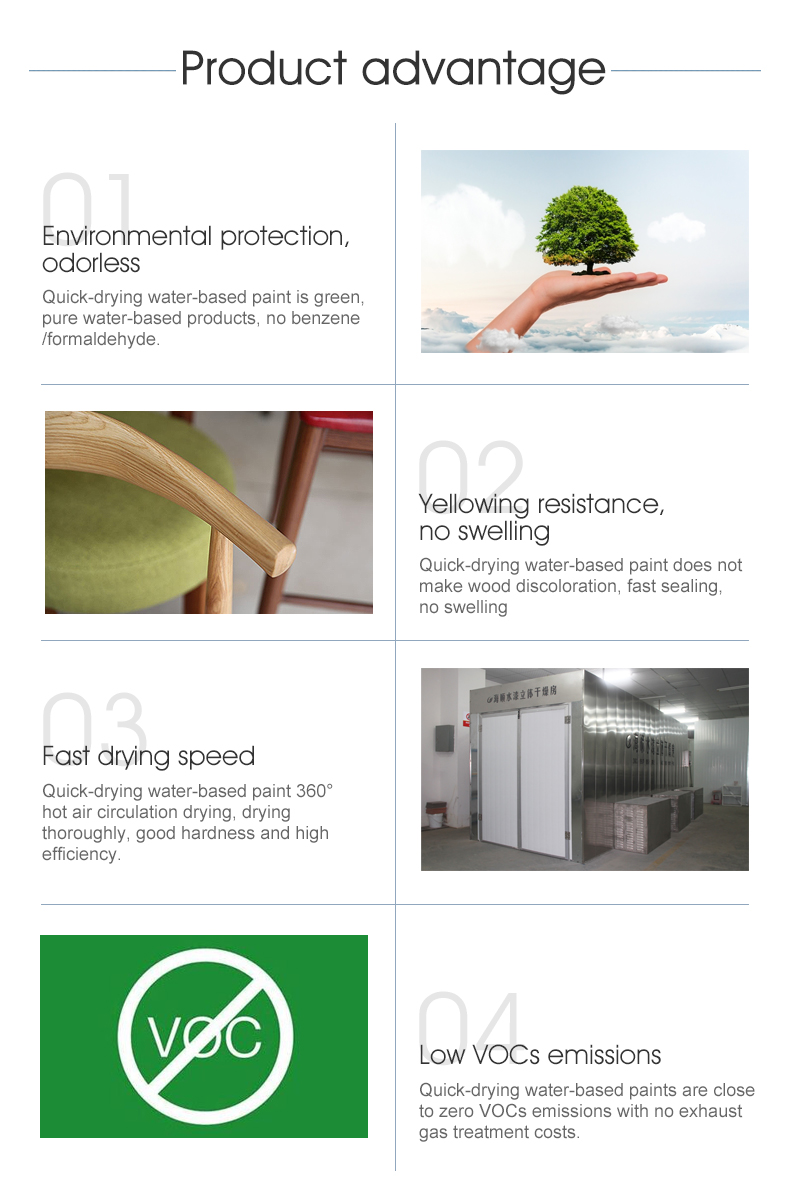

[Product Features]

Quick drying.

Good sealing.

Anti- yellowing.

Suitable for varnish coating system.

[Implementation Standards]

Q/HS013-2019

[Packaging and Storage]

20kgs/barrel.

Store indoors at room temperature, shelf life: 6 months.

[ApplicationTechnique]

Surface treatment: the surface of the substrate must be clean, dry, dust-free, oil-free, impurities-free, and polished flat.

Application methods: roll coating, through leveling machine and baking dry for 15-20 seconds.

Dilution ratio (weight ratio): GTX-E13:Water = 100:0-10(water dosage will vary according to different application environment and application methods.)

Application viscosity: roll coating 130"to 160" (coating 4 cups/25 ℃).

Matching system:need to be matched with our company’s primer.

[Note]

Water-based products cannot be mixed with oil-based products,otherwise, it will be insoluble.

Use and mix immediately, stir well and stand for about 15 minutes to eliminate bubbles generated during stirring.

Application indoor temperature: 5℃-40℃.

Application environment: if the air pressure is lower than 1 atmosphere, please test before application.

Keep the application environment clean and avoid mixing of oil, dust and impurities during application.

Coating should not be too thick, in case of slow drying,cracking and other defects. The recommended roll coating dosage is 25-45g/㎡.

If the surface is flat and no need to be polished when roll coating.

If the water paint is not be used up at one time, in case of affecting the quality and application effect of water paint due to volatilization or inhalation of impurities, it must be sealed immediately.

[Technical Indicators]

|

Item |

Solid content,% |

Fineness,μm |

PH value |

|

Parameters |

37±2 |

≤60 |

8.5±1 |