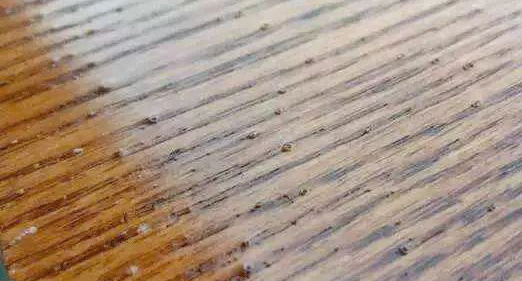

When it comes to the number one problem in construction, the prickly heat needs to wear off the coating and re-construct it, which is time-consuming, time-consuming and material-consuming. It is called the "painting nightmare" of furniture factories. The bright clear topcoat with high resin content and the clear primer with low powder content are the hardest hit areas for prickly heat! If you want to stay away from these problems, you must have a thorough understanding of prickly heat.

1. Prickly heat vs Blistering

Shape and Definition: Prickly heat and blisters are both formed during drying. Judging from the shape, the dense and many incomplete hollow protrusions are prickly heat; the relatively large and hollow air bubbles are blistering.

Cause: Both are caused by too fast surface drying. If the solvent in the paint film is not released in time, it will cause prickly heat; if the gas is not discharged in time, it will cause foaming.

Prevention ideas: The causes are different, and there are fundamental differences in prevention ideas. For prickly heat, there are two factors for dismantling from the formation mechanism: (1) the surface drying is too fast, and (2) the solvent in the paint film is not released in time.

2. How to delay the surface drying speed?

Cooling in the drying room: high temperature in summer is the norm, usually ≥30°C during the day, and ≥35°C in many areas. The higher the temperature, the faster the surface drying, and the suitable drying temperature is 25℃-30℃. It is recommended to install cooling equipment to control the temperature of the drying room.

Add slow-drying diluent: When the construction temperature is ≥35℃, slow-drying diluent or appropriate amount of slow-drying water can be added (the addition amount does not exceed 25% of the weight of the diluent) to appropriately extend the surface drying time.

Special reminder: The real estate thinner may have the following conditions: ①High water content; ②The raw material is recycled from waste material, the volatilization rate is fast, and the drying rate is unbalanced; ③The solubility is poor.

Based on the above situation, such as the use of real estate thinners, it is not the addition of slow-drying solvents that can solve the problems of prickly heat, foaming, pinholes, etc., but the influence of the solvent's volatilization rate balance and solubility.

3. How to release the solvent in the paint film in time?

Coating curing and film formation: the combination of solvent volatilization drying process and crosslinking reaction curing process, the volatilization rate of solvent in the coating film directly affects the drying process, thereby affecting the prickly heat formed by solvent volatilization. Therefore, you can start from 3 aspects:

Timely replacement of seasonal supporting products, curing agent and diluent are the main factors that affect the speed of solvent volatilization.

Therefore, it is necessary to select the matching curing agent and diluent according to the change of temperature and humidity, especially after the rainy weather in summer, the temperature rises rapidly, and it is necessary to switch the supporting products in time.

Avoid one-time thick coating, the thicker the paint film, the slower the solvent will evaporate. Therefore, when spraying, do not apply a one-time thick coating, which can allow the solvent to evaporate from the coating faster.

By controlling the air flow speed, the continuous volatilization of the solvent in the paint film will make the solvent concentration in the air of the drying room rise continuously.

Therefore, the spacing between the layers of the boards to be dried should not be too dense, and the air flow speed of the drying room should be appropriately accelerated to allow the volatilized solvent to be discharged in time.

So, we have a multi-dimensional comparison of prickly heat and blisters to help you understand them better and get rid of them!